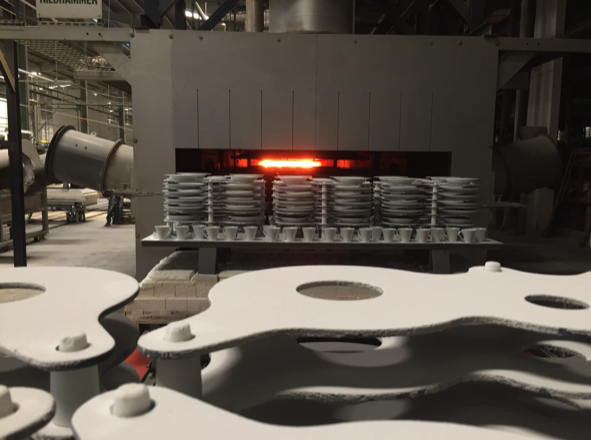

Firing helpers

Kiln furniture in porcelain production

Firing aids in porcelain production are refractory kiln accessories that are used in the firing processes of porcelain as carrier plates, supports, cassettes, firing racks, etc. The material and thickness of the firing aids play an important role in the production costs, because the higher the proportion of firing aids in relation to the porcelain, the more expensive the firing process is due to loss of space. Modern, flat and thin support systems as firing aids can thus not only save production costs, but also make a contribution to environmental protection by saving energy and reducing emissions.

In the following we will briefly describe the best known materials of kiln furniture in porcelain production.

Cordierite oven panels

Cordierite, obsolete also known as dichroite or iolite, is a rather rare mineral from the mineral class of “silicates and germanates”. It crystallises in the orthorhombic crystal system with the idealised chemical composition Mg2Al3[AlSi5O18][1] and is therefore chemically speaking a magnesium-aluminium silicate. The Strunz classification of minerals assigns cordierite to ring silicates, but according to its structure, cordierite is a framework silicate.

Cordierite is the magnesium analogue of secaninaite (Fe2Al3[AlSi5O18]) and forms a complete solid solution series with it. For this reason, the mixed formula (Mg,Fe)2Al3[AlSi5O18][2] is often given for cordierite, whereby the elements magnesium and iron in the round brackets may represent each other in the formula (substitution, diadochy), but always in the same quantitative ratio to the other components of the mineral.

In nature, cordierite rarely develops well-formed, short to long prismatic crystals. Mostly it is found in the form of granular to massive aggregates. However, crystals up to half a metre in length have been found. [7] Undamaged crystal surfaces have a glass-like lustre, whereas fractured surfaces have a more grease-like lustre.

The predominant colour of cordierite is deep blue to blue-violet, but it rarely occurs in greenish, yellowish-brown, grey or light blue. Even colourless cordierites are known. With a Mohs hardness of 7 to 7.5, cordierite belongs to the hard minerals which, like the reference mineral quartz (7), are able to scratch glass. As a rule, kiln plates made of cordierite are suitable for firing up to 1,300 °C.

Cordierite-mullite stove plates

This is a cordierite-mullite compound that achieves a temperature resistance of up to 1,320 °C.

Corundum-mullite stove plates

Corundum is one of the most important industrial minerals and finds a wide range of applications due to its high chemical and temperature resistance as well as its high hardness and abrasion resistance. Corundum is a relatively frequently occurring mineral from the mineral class of oxides and hydroxides. It crystallises in the trigonal crystal system with the chemical composition Al2O3 and is therefore chemically speaking aluminium oxide. Corundum is the reference mineral for the Mohs hardness 9 on the scale reaching to 10 (diamond) according to Friedrich Mohs. It usually develops long, prismatic or columnar to barrel-shaped crystals, but also granular aggregates, which can have different colours depending on the impurity. In chemically pure form, corundum is colourless. Well-known varieties with the same composition and crystal structure are ruby (red due to traces of chrome) and sapphire (different colours, including blue due to iron or light red due to titanium).

The surfaces of the translucent to transparent crystals have a glassy to diamond-like, often somewhat greasy shine. Corundum has no cleavability, but is very completely separated from the twin surfaces, which have a pearlescent shine. Due to its brittleness, it breaks like glass or quartz, whereby the fracture surfaces are conchoidal to splintery. The largest corundum crystals known so far have reached a length of about one metre and a weight of up to 152 kg.

Kiln furniture made of corundum mullite can be used for firing temperatures up to 1,650° C.

Silicon carbide

Silicon carbide is a chemical compound of silicon and carbon belonging to the group of carbides. The chemical formula is SiC. Silicon carbide products are high-quality refractory materials with the advantages of fine thermal conductivity, high thermal shock stability, high load capacity softening point and very good wear resistance. SIC furnace plates, or recrystallised silicon carbide (R-SiC), generally do not require a release agent and glaze residues can be easily removed from high-quality designs.

Kiln furniture made of high-quality silicon carbide can be used for firing temperatures of up to 1,600 °C.

Release Agent

Release agent is a sandy powder of calcined alumina and dextrin, which serves as a release agent for the protection of cordierite kiln plates. It is distributed as a protective layer on the kiln plate and absorbs the draining glaze drops without damaging the kiln plate.